Polyester PET

PROCESSABILITY OF POLYESTER

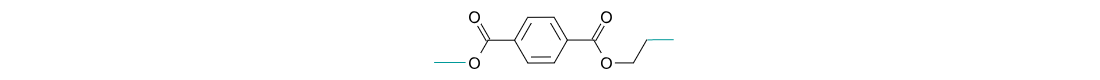

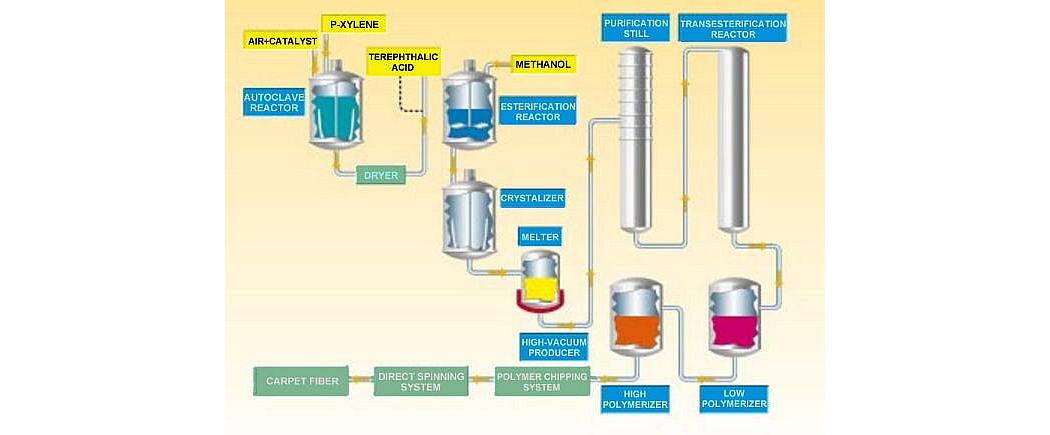

Most polyesters are made from petroleum from which the constituent acids and alcohols are derived. The types of processes that manufacturers use vary, and little is known about specific manufacturing processes, because the companies want to keep them a secret in order to remain competitive. Here is a general description of how polyester is synthesized:

- Polymerization

Condensation polymerization occurs when the acid and alcohol are reacted in a vacuum at high temperatures. The polymerized material is extruded in the form of a ribbon onto a casting trough or cooling wheel. After the ribbon hardens, it is cut into chips.

- Spinning

The chips are dried and then put into hopper reservoirs for melting. Polyester is a "melt spun" fiber, which means that it is heated, extruded through the spinnerets, and cools upon hitting the air. From there it is wound around cylinders.

- Drawing

The fibers are then hot stretched until they are about five times their original length in order to decrease their width. The drawing results in a optimal orientation of the molecules inside the fiber and results in a perfect strength.

VARIATIONS ON THE BASIC POLYMER

Different fibers can be created by doing one or more of the following:

- Adding a delusterant (dulling agent)

Polyester is a naturally bright fiber, but can be made dull or semi-dull by the addition of a TiO2.

- Changing the shape of the holes in the spinneret

The simplest and most common shape is a circle, but by changing the shape of the spinneret, square, oval, and bean-shaped fibers can be formed. One can even create a hollow fiber. The different shapes affect the hand and strength of the fiber.

- Drawing it out more

Drawing out the fiber to five times its original length is normal, but polyester can be stretched even further. Drawing it out more than normal may also affect the strength, elasticity, and dye-ability.

- Adding dye stuffs

In its natural state, polyester is a slightly transparent off-white. Adding dye stuffs at the manufacturing stage can create brilliant colors like electric blue and atomic red. In this field, one of the World leader was Setila with its "Decora" programme, especially for the automotive industry where extremely high fastness requirements are demanded

- Crimping

When the fiber is drawn out it is long and smooth. Crimping can give the fiber more texture and bulk and can increase its insulation properties, as well as its elasticity. Another word for this is texturizing.

MAKING YARNS

After the fiber itself is created, it is made into a yarn. There are two types of polyester yarns: filament and spun. Filament yarns are made by taking the single polyester filaments, grouping them together and then twisting or air-entangling them to make them workable.

A monofilament yarn has just one, single polyester fiber that is usually not twisted. Spun yarns are produced in much the same way as a cotton or wool yarn is produced. The long filaments are fist cut into short pieces called staple. These are then combined together and spun to create a yarn made up of thousands of short filament.

BLENDS

At this stage, polyester can also be combined with other fibers to produce a variety of effects. Polyester and cotton is probably the most famous and popular blend. The polyester helps the fabric retain its shape and resist stains and wrinkles. The cotton makes the fabric more absorbent and comfortable.

Polyester is combined with wool to give it wrinkle-resistance and shape retention in all kinds of weather. Since polyester is stronger than wool, it increases the durability and life of the fabric. The wool contributes good draping characteristics and elasticity.

Polyester and rayon is another popular blend fabric. Here again the polyester makes the fabric more resilient and durable, and helps it keep its shape. The rayon adds a different texture, has a good hand, is good for draping, and is more absorbent.

Polyester and nylon produce a strong fabric because of nylon's strength and abrasion resistance and polyester's wrinkle-free properties. This combination produces a yarn that is strong, durable, stable, easy to launder, and resistant to mildew and insects. Problems with this blend, however, are that pilling may occur, and it does not have a very nice hand. Furthermore, since neither nylon nor polyester is very absorbent, the fabric may feel wet and clammy in warm or humid weather.

WEAVING

After the yarns are made, they are shipped out to textile mills to be woven into fabric. Polyester can be made into both woven and knitted fabrics (such as the infamous double-knit!).

FINISHING PROCESSES

Finally, after the fabric is made, one or more of the following finishing processes is used to improve the quality of the fabric:

- heat setting

creates a permanent shape

- singeing

improves the hand, reduced pilling and increases smoothness

- anti-static finish

reduced static electricivty

- resin finishes

increases ease of care

- water and stain repellency

increases comfort and makes it easier to clean, also used for rainwear

- calendaring

increases smoothness and reduced pilling

- embossing

creates a design and/or a luster