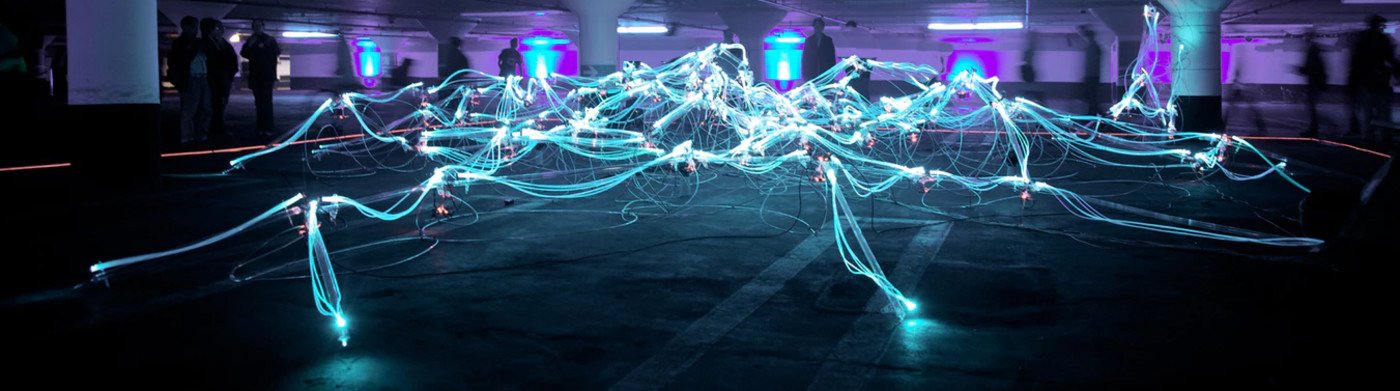

In the world of tommorrow, the megatrends of today will be embedded into our daily lifes. The Internet Of Things will have arrived, enabling daily life articles to be connected to devices in order to interact with them. This development does not stop in the textile field: wearable technologies, e-textiles or smart textiles, meaning fabrics with sensors incorporated (like RFID), open a new world in terms of innovation and possibilities.

A NEW WORLD

Sensors and fabrics however do not stand in contradiction. Over are the times, where brittle fine wires needed to be somehow added to the farbic, attempting to combine flexibility with conductivity - but failing miserably at it.

Nowadays, a variety of elegant, conductive solutions exist on the market: conductive yarns that combine low resistivity values and flexibility without compromising the conductive performance of a yarn. Such yarns, like SwicoSilver HiCon or the plasma metal coated ones, enable new production methods for sensors, meaning the conductivity can be incorporated directly into a fabric by weaving, knitting or embroidery for example.

Nowadays, a variety of elegant, conductive solutions exist on the market: conductive yarns that combine low resistivity values and flexibility without compromising the conductive performance of a yarn. Such yarns, like SwicoSilver HiCon or the plasma metal coated ones, enable new production methods for sensors, meaning the conductivity can be incorporated directly into a fabric by weaving, knitting or embroidery for example.

CONDUCTIVITY MEETS YARN

Conductivity on yarns can be reached via various production techniques: plasma metal coating, chemo galvanic coating, stainless steel yarns, pure metal fine wires or carbon loaded yarns to name a few. Depending on the type, those techniques can be applied on filament yarns, spun yarns and fibers.

This diversity in production techniques consequently enables to meet all customer requirements as there is no such thing as "the" conductive yarn. Rather, there are solutions for applications where high or low conductivity values are required.

Conductive yarns include:

This diversity in production techniques consequently enables to meet all customer requirements as there is no such thing as "the" conductive yarn. Rather, there are solutions for applications where high or low conductivity values are required.

Conductive yarns include:

- SwicoSilver (including HiCon type)

100% silver coated PET filament yarn - or any other substrate that is an endless filament yarn of any material. Thanks to the plasma metal coating process, metal is directly brought onto the substrate without any adhesive layers - for perfect workability, excellent conductivity values and a long functional life span.

SwicoSilver yarns are good for knitting, weaving, twisting, embroidering and braiding - they are resistant to washing.

- SwicoGold

100% 24K gold coated PET filament yarn - or any other substrate that is an endless filament yarn of any material. Thanks to the plasma metal coating process, metal is directly brought onto the substrate without any adhesive layers - for perfect workability, excellent conducitivty values and a long functional life span.

SwicoGold yarns are good for knitting, weaving, twisting, embroidering and braiding - they are resistant to washing.

- plasma metal coated yarn

The metal of your desire on a PET filament yarn - or any other substrate that is an endless filament yarn of any material. Thanks to the plasma metal coating process, metal is directly brought onto the substrate without any adhesive layers - for perfect workability and a long functional life span. Including the advantage of having the properties of the metal on a textile yarn.

Plasma metal coated yarns are good for knitting, weaving, twisting, embroidering and braiding - they are resistant to washing.

- fine inox wire

This fine Inox wire is available in a mixture with polyvinyl alcohol PVA in a count of 560 dtex. The PVA yarn is wrapped around the Inox to enable a good workability. In the finishing process the PVA part is dissolved and as a result one gets a 100% Inox fabric / product.

- silver coated polyamides

In different counts, we can provide you a PA 6.6 or PA 6 mono- and multifilament yarn which is coated with silver by the chemical process.

- carbon containing yarns

like Belltron, a high performance carbon fiber, as well as mixed with Polyester multifilament for easy weaving - to suit your requirements and to sensure an excellent runability of the yarn.

TAKING THE SHOCK OUT OF TEXTILES

Conductive fiber technologies are also tools for development in markets where unacceptable static discharge raises quality, health and safety concerns with carbon yarns or Polyaniline PANI.

As many textile manufacturers search for non-commodity opportunities that add value for their customers, products developed for electrostatic discharge (ESD) control have shown promise. Whether for traditional clean-room apparel fabrics or antistatic conveyor belts, products that dissipate electrical charges continue to find their way into a broad array of markets.

In the automotive industry, product applications include seatbelts and upholstery. Bulk bags, antistatic brushes and conveyors and paper-forming belts make manufacturing safer and more efficient. Antistatic brushes inside printers are widely used hidden components. The commercial environment has benefited from using antistatic engineered commercial upholstery and flooring products — and the list goes on.

As many textile manufacturers search for non-commodity opportunities that add value for their customers, products developed for electrostatic discharge (ESD) control have shown promise. Whether for traditional clean-room apparel fabrics or antistatic conveyor belts, products that dissipate electrical charges continue to find their way into a broad array of markets.

In the automotive industry, product applications include seatbelts and upholstery. Bulk bags, antistatic brushes and conveyors and paper-forming belts make manufacturing safer and more efficient. Antistatic brushes inside printers are widely used hidden components. The commercial environment has benefited from using antistatic engineered commercial upholstery and flooring products — and the list goes on.

SHIELDING

Offering shielding and conductive filament yarns which are engineered to run well in weaving warp and weft.

Furthermore, there are also fabrics for shielding available by Swiss Shield - the textile concept which protects you.

- Polyester PET with carbon

Intimate mixtures of polyester filament yarns with carbon products (Belltron) in counts from dtex 50 up to dtex 610.

The polyester provides the textile properties according to your final product requirements and carbon component the necessary conductivity or shielding performance.

- Polyester PET filament with copper monofilament

Intimate mixtures of polyester filament yarns with highly conductive copper monofilaments which may be coated with silver or polyurethane products in counts from dtex 50 up to dtex 610.

The polyester provides the textile properties according to your final product requirements and the copper monofilament component the necessary conductivity or shielding performance.

Furthermore, there are also fabrics for shielding available by Swiss Shield - the textile concept which protects you.