Polypropylene PP

PROPERTIES OF POLYPROPYLENE

Polypropylene has the following properties:

- fairly low physical properties

- fairy low heat resistance

- excellent chemical resistance

- translucent to opaque

- "living hinge" capability

- low price

- easy to process

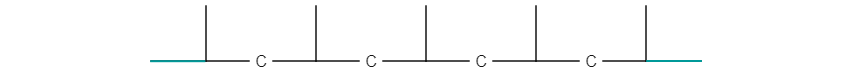

Heat setting removes the residual strains and produces a defect-free and stable crystalline structure to make fiber/fabrics dimensionally stable. It also improves the percentage of overall crystallinity. The smectic structure changes to more perfect monoclinic structure during the process of heat setting if the temperature is above 70°C . At 145°C the conversion is almost complete. In comparison to predominantly smectic form, the monoclinic form does not experience any major change in crystalline structure during the course of drawing and heat setting.

FIBER CHARACTERISTICS THANKS TO POLYOLEFIN ORIGIN

- able to give good bulk and cover

- resistant to abrasion, deterioriation from chemicals, mildew, perspiration, rot, stain, soil and weather conditions

- colorfast

- quick drying

- low static

- thermally bondable

- strong

- dry hand (transports body moisture from the skin)

- very comfortable and lightweight

MECHANICAL PROPERTIES

The general physical properties of PP fibers are shown in Table 1. Polypropylene fibers are produced in a variety of types with different tenacities designed to suit varying market requirement. Fibers for general textile uses have tenacities in the range of 4.5-6.0 g/den. High tenacity yarns up to 9.0 g/den are produced for the use in ropes, nets and other similar applications. High performance PP fibers have been made with high strength and high modulus. The techniques include ultra-drawing, solid state extrusion and crystal surface growth. The filaments with tenacities over 13.0 g/den can be made.

| Moisture regain | 0.1% |

| Refractive index | 1.49 |

| Heat of fusion | 21 cal/g |

| Specific heat | 0.46 cal/(g x C) |

| Density of melt at 180°C | 0.769 g/cc |

| Heat of combustion | 19400 Btu/lb |

| Oxygen index | 17.4 |

| Decomposition temp. range | 328 - 410 °C |

| Dielectric constant (0.1 MHz) | 2.25 |

| Dissipation factor (0.1 MHz) | < 0.0002 |

The degree of orientation achieved by drawing influences the mechanical properties of PP filaments. The greater the degree of stretch, the higher the tensile strength and the lower the elongation. Commercial PP monofilaments have an elongation at break in the region of 12-25%. Multifilaments and staple fibers are in the range of 20-30% and 20-35%, respectively.

THERMAL PROPERTIES

Polypropylene fibers have a softening point in the region of 150°C and a melting point at 160-170°C. At low temperatures of -70°C or lower, PP fibers remain their excellent flexibility. At high temperature (below 120°C). PP fibers nearly remain their normal mechanical properties. PP fibers have the lowest thermal conductivity of all commercial fibers. In this respect, it is the warmest fiber of all.

DYEABILITY

The dyeability of fibers is controlled by both chemical and physical properties. Fibers that have polar functional groups in their molecular repeat units are easier to be dyed. These polar groups may serve as active sites for the combination with dye molecules by chemical bonds.

Since PP molecular chains have no polar functional groups, the dye molecules can not be chemically attracted to the fibers. The dye molecules can not even be strongly adsorbed by the fiber surfaces because of their hydrophobic properties. Therefore, these adsorbed molecules, which interact with the fiber surface by weak Van Der Waale's force, are easily washed away.

In addition, PP fiber has relatively high crystallinity (50-65%) which partially attributes to its very low dyeability. Fiber modifications have been investigated to make polypropylene dyeable, which include copolymerization to provide dye sites along the macromolecular chain and blend with dyeable polymers.

OTHER PROPERTIES

In general, PP fiber has excellent chemical resistance to acids and alkaliks, high abrasion resistance and resistance to insects and pests. PP is also easy to process. Its low moisture absorption helps quick transporting of moisture.

The main drawbacks of PP are:

- low melting temperature which prevents PP from being ironed like cotton, wool or nylons

- hard to be dyed right after manufacturing except being modified

- high crystallinity and poor thermal conductivity leads to limited texturizability

- poor UV and thermal stability, which required the addition of expensive UV stabilizers and antioxidants

- poor resilience compared to PET and nylons

- low creep

- poor adhesion to glues and latex

- flammable which melts and burns like wax