Polypropylene PP

POLYPROPYLENE FIBERS

Polypropylene staple fibers for applications like:

- non wovens

- reinforcement

- filtration

- paper production

Also available: PP fibers made from plant waste generated in industry.

In general, polypropylene fibers are available as follows:

| count | dtex 1.0 - dtex 11.0 |

| cutlength | 1mm - 75mm |

| put up type | bags in pallet boxes or bales |

Polypropylene fibers are furthermore very popular for adding to concrete for the reasons:

- to prevent micro cracks from happening in the concrete

- nicely closed surface of the concrete, meaning less corrision and a longer life

- to reduce damage in concrete in case of a fire

This is due to the key properties of such especially developed:

AFC and MCP fibers

- They contribute to a clear improvement of the concete quality

- They are harmless from a medical point of view and do not enter the lungs (like asbesots for example that was prohibited from 1990)

- They are used to prevent cracks in asphalt concrete (road construction). The consequently reduced maintenance expenditure can be offset against slight extra costs (use of fibers).

- They also achieve very good results in grouting compounds, joint adhesives etc.

- They are chemical resistant, environmental firendly, do not rot an are corrosion resistant.

- AFC fibers have been especially developed fror fireproof concrete qualities (pressure compensation by means of cavities) - at the same time however fulfills the function of MCP (improvement of the concrete properties).

- AFC fibers are also used in tunnel construction (inner shell) and therefore make a significant contribution to safety in case of a fire. The explosion type flaking and pieces of concrete falling down due to excessive heat can almost be avoided.

Advantages of AFC and MCP fibers

- reduction of segregation, plastic shrinkage and permeability

- improved hydration

- reinforcing fibers are anchored

- impact and abrasion resistance is increased

- corrosion is slowed

- maximizes Toughness Index

Cement, aggregate, and sand tend to settle to the bottom of the concrete. AFC and MCP fibers hold these heavier materials in place for more uniform density. Bleed water is held in the concrete longer for more effective cement hydration.

AFC and MCP fibers stop most of the cracks created by plastic shrinkage. AFC and MCP fibers act at tiny springs which absorb the sudden shock of impact. This elasticity of fiber firmly anchored in the concrete results in the large increase in resistance to impact and abrasion. AFC and MCP fibers reduce the permeability, slow the migration to primary steel of corrosive elements such as chloride ions.

The Toughness Index, the ability to sustain a load after first crack, is maximized by using strong fibers which do not pull out under load. Three dimensional secondary reinforcement replaces wire mesh for a better concrete at a lower cost.

AFC and MCP fibers are easy to use. Any concrete admixture may be added to the concrete without any change due to the presence of the fibers. Polypropylene fibers are highly resistant to both acid and alkaline environments. Pumping of the concrete remains the same, and fibers could reduce the amount of pump pressure.

AFC and MCP fibers are safe to use, non-toxic, non-irritant. AFC and MCP fibers are extruded only from virgin polypropylene resin under extreme quality control standards. They are always identical size, shape, strength, and performance.

Impact strength / Ductility

AFC / MCP fibers give the composite a certain ductility. The three-dimensional embedded elastic material minimizes the susceptibility to brittle fracture without bringing any disadvantage in relation to the strength of the concrete.

For this reason alone fibres are given preference in the manufacture of pre-fabricated parts. to prevent handling and transport damage.

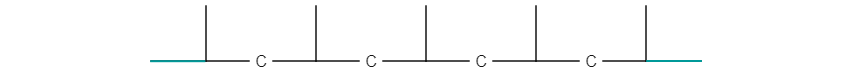

The illustration above shows an expert opinion carried out using an electron microscope on the surfaces of fracture of a piece of concrete using AFC / MCP fibers.

The homogenous distribution of the AFC / MCP fibers - fibres clearly showed the fibres all projected from the hardened cement paste matrix individually.

No cluster formation was recognizable. When assessing the fibre surface using 4000 x magnification (right hand) illustration it could be seen that close particles of hardened cement paste point to a good bond between the hardened cement paste matrix and the fibers - this is achieved using a special finish from asota®.

Effect in green concrete

One problem in concrete components is the formation of micro cracks during the hardening or curing time that subsequently widen out to cracks due to shrinkage. Without the addition of AFC / MCP fibers, the relevant after treatment only provides a partial counteraction.

AFC / MCP fibers take up the stresses occurring during the hardening process and provides for a balanced level of humidity in the matrix due to the greater retention ability. Less water thus collects on the surface (anti-bleeding) and one can speak of an "internal after treatment" of the concrete here. Many tests have confirmed the increased early strength that can be made use of above all due to reduced casing periods and faster slip-form construction.

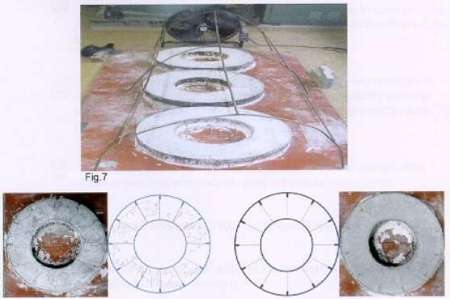

Reduction cracks due to shrinkage by up to 99.5%

Tests to represent the crack formation were carried out with (right) and without (left) AFC / MCP fibers.