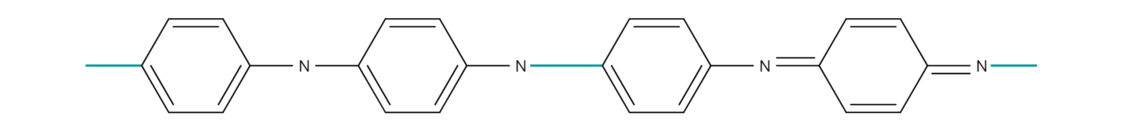

Polyaniline PANI

ADVANTAGES OF POLYANILINE PANI

Polyaniline PANI convinces with the following advantages:

- wide and controllable range of conductivity

The electrical conductivity of polyaniline based compositions can be closely controlled over a wide range. For neat polyaniline compositions conductivity levels as high as 100 S/cm can be achieved. The full range of conductivity levels from less than 10-10 to 10-1 S/cm (melt processing) and 10 S/cm (solution processing), can be achieved for polymer blends containing polyaniline compositions. An important advantage is that the classical high percolation threshold for the onset of electrical conductivity observed in globular carbon black filled plastics, does not exist.

- melt and solution processable material

Polyaniline based compositions can be processed using conventional techniques such as blow and injection moulding, extrusion, calendering, film casting, and fibre spinning. These compositions withstand temperatures as high as 230-240°C for short periods of time (5-10 minutes) without significant change in electrical properties, and can be melt blended with many commodity polymers. Selected industrial solvents can be used for solution processing neat polyaniline compositions.

- conductive blends with many commodity polymers

Electrically conductive polyaniline based blends with commodity polymers can be produced by using common solution and melt processing techniques. Examples of commodity polymers are polyethylene, polypropylene, polystyrene, PVC, phenol-formaldehyde resins, and different types of thermoplastic elastomers. Unlike conventional filled materials, the mechanical properties of these blends are close to those of the insulating matrix polymer.

- function as processing aids in addition to providing conductivity

Plasticised polyaniline compositions improve melt processing performance by lowering the melt-viscosity, lowering the processing temperature and shortening the processing time. The improved melt flow properties make, for example injection moulding of complex shapes easier.

- coloured and transparent electrically conductive products

Electrically conductive, coloured and transparent thin films and coatings, which would otherwise be difficult to achieve with conventional filled materials, can be made using polyaniline based compositions.